The world is currently experiencing technological transformation that will fundamentally change the way we live and work. It is difficult to predict precisely how this transformation will impact different industries and countries.

Industry 4.0 transforms how products are designed, fabricated, used and operated, maintained and serviced. It will also transform the operations, processes, supply chain management and energy footprint of factories, leading to the future of work

This leads us to a pertinent question. What is the future of work? The future of work can be described as rapid digitalisation and globalisation that have sparked radical shifts in how we live and work. The coronavirus (COVID-19) crisis has accelerated these beyond anything we could have imagined. These changes raise essential questions about the precocity of our jobs, the support available if we’re unable to work or retire, the skills we need for current and future employment, the quality of those jobs, and the voice we have in shaping these outcomes.

New Technology Era

Many see these changes as ushering in a new era of growth, change and opportunity. The ramifications for manufacturing firms force nations and governments to re-evaluate how the manufacturing industry operates and contributes to economic growth. Countries are now increasing their focus on developing advanced manufacturing capabilities by investing in high-tech infrastructure and quality education. These are done by facilitating the transformation of the manufacturing industry to the next technology frontier and raising their economic well-being.

Driving Forces & Stages of Industrialisation

The first industrial revolution was driven by the invention of steam machines, which then led to the industrial transformation of society with steam engine trains becoming a crucial mode of transportation as well as the mechanisation of manufacturing that expedited production.

The second industrial revolution was typically seen as the period where electricity and new manufacturing ‘inventions’ was enabled, which led to the development of the assembly line and mass production. These also paved the way for the beginnings of automation.

The third industrial revolution had everything to do with the development of computers and computer networks (WAN, LAN, MAN,…) which led to the rise of robotics in manufacturing, and the birth of the Internet; a game-changer in the way that information is handled and shared. This also resulted in the creation of electronic (or “e”) versions of documents and communications, as well as a greater emphasis on automation.

In the fourth industrial revolution, we move from ‘just’ the Internet and the client-server model to ubiquitous mobility, the bridging of digital and physical environments (in manufacturing referred to as Cyber-Physical Systems), the convergence of IT and OT, as well as other well-established technologies that include the Internet of Things, Big Data, cloud computing and more. These are complemented by additional accelerators such as advanced robotics and AI/cognitive computing which enable greater automation and optimisation of new processes. These have enabled businesses to work more effectively in the short term while expanding market reach and transforming their business model in the long term.

Global Landscape

Industry 4.0 changes the global landscape of manufacturing competition, reducing the relative competitive advantage of low-cost regions that rely on cheap labour. Nations and manufacturing firms that lead the way in embracing Industry 4.0 technologies and processes will gain over global competitors. This competitiveness hinges on the ability to transform by responding to market shifts and technology trends. The transformation of the manufacturing industry, through Industry 4.0, is also in line with the United Nation’s Sustainable Development Goals (SDGs).

Technologies shaping Industry 4.0

- Industry 4.0 is in the process of revolutionising manufacturing and engineering all over the world.

- No conversation about its significance is complete without looking at the talent required to make it work for us.

- In the next five to 10 years, companies will have to adapt to or adopt Industry 4.0 technologies and principles to compete and survive.

- Like it or not, that means investing in the right people and skill sets today, to ensure a favourable position well into the future.

- The following rundown of four major skill groups is far from comprehensive. Nevertheless, it should serve as a solid blueprint for companies that want to create new positions and invest in their technology portfolio.

Ten skills for the Fourth Industrial Revolution:

- Complex problem solving

- Critical thinking

- Creativity

- People Management

- Coordinating with others

- Emotional intelligence

- Judgement and decision making

- Service orientation

- Negotiation

- Cognitive flexibility

Source: Future of Jobs Report, World Economic Forum

Industry 4.0 Implementations and Jobs

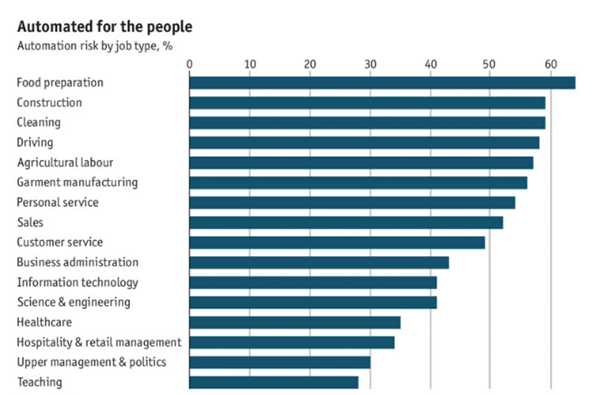

The 4th Industrial Revolution will impact nearly every industry, with The Economist predicting that 50% of jobs are vulnerable to automation. However, some industries are more likely to be automated than others as robots, like human employees, have a specific skill set.

We can expect to see a reduction in the number of full-time staff in manufacturing and agricultural roles within the near future as many of these positions are already being phased out due to increased automation. Robots can also more effectively and safely handle tasks within industrial plants – their use in manufacturing dates back to the 1970s. The OECD released a list showing the likelihood of roles within specific industries becoming obsolete or automated. At the top of the list are occupations within food preparation, construction, cleaning, driving and agricultural sectors.

Source: OECD

The Future

In the next five to 10 years, companies will have to adapt to or adopt Industry 4.0 technologies and principles to survive and compete. Like it or not, that means investing in the right people and skill sets today to ensure a favourable position well into the future. The following rundown of four major skill groups is far from comprehensive. However, it should still serve as a solid blueprint for companies that want to create new positions and invest in their technology portfolio. According to Mercer’s Global Talent Trends2020–2021, 3D printing and robotics have intensively upended the automotive industry. For many car manufacturers, like the BMW Group, such disruption is the driver of transformation. The challenge is attracting, motivating, and retaining people with competencies different from the traditional mechanical engineer and focusing more on employees and candidates who display digital dexterity.

Transform the Workforce by Reskilling

With transformation an everyday reality, reskilling is one of the most significant opportunities of the decade. Without accelerating our progress on the skills plan, we would not have the talent to take advantage of the new jobs we’re creating. Transformation is both a business and a HR challenge, and it demands organisation-wide interventions to deliver results. Companies that unlock reskilling at speed and scale will transform at a pace that leaves their competitors behind. KeyBank has enabled 4,000 colleagues (from an 18,000-person workforce) to start reskilling towards emerging new roles and career paths for the past few years. First, it deployed a “volunteer army” to research the future of work conceptually while developing practical examples and stories of the learning journey KeyBank colleagues are making to become the “CEOs of their careers.” This work led to a “Future Ready Workforce” programme centred on four workstreams: defining skills needed now and in the future; creating a “job marketplace”; continual training and learning; and change management and communication.

Dr. Mehrunishah Begum is part of the National Human Resource Centre’s (NHRC) Policy Development team. Her current role at the NHRC involves carrying out policy research at the national level. She comes from a strong academic background with a Doctor of Philosophy (PhD) in the field of Knowledge Transfer & IHRM. She’s an experienced academic and researcher with a demonstrated history of working at HEIs and American MNCs. Dr Nishah’s teaching forte include Global Human Resources Management, Entrepreneurship, Personal & Professional Development.

WHAT HAPPENED TO JOBS AT HIGH RISK OF AUTOMATION?© OECD 2021POLICY BRIEF ON THE FUTURE OF WORKWhat happened to jobs at high risk of automation?. (2021). Retrieved 25 June 2021, from https://www.oecd.org/future-of-work/reports-and-data/what-happened-to-jobs-at-high-risk-of-automation-2021.pdf

Recruitment, C. (2021). How Will the Fourth Industrial Revolution Impact the Future of Work? – Change Recruitment. Retrieved 25 June 2021, from https://www.changerecruitmentgroup.com/knowledge-centre/how-will-the-fourth-industrial-revolution-impact-the-future-of-work

TOP 10 skills you need in the Fourth Industrial Revolution. (2021). Retrieved 25 June 2021, from https://www.linkedin.com/pulse/top-10-skills-you-need-fourth-industrial-revolution-cezar-maroti/

WIN WITH EMPATHY Global Talent Trends2020–2021. (2021). Retrieved 25 June 2021, from https://www.mercer.com/content/dam/mercer/attachments/private/global-talent-trends/2021/gl-2021-gtt-global-eng-mercer.pdf

Global Talent Trends 2019. (2019). Retrieved 25 June 2021, from https://business.linkedin.com/content/dam/me/business/en-us/talent-solutions/resources/pdfs/global-talent-trends-2019.pdf

Industry 4.0: the fourth industrial revolution – guide to Industrie 4.0. (2021). Retrieved 25 June 2021, from https://www.i-scoop.eu/industry-4-0/

K. Zervoudi, E. (2021). Fourth Industrial Revolution: Opportunities, Challenges, and Proposed Policies. Retrieved 25 June 2021

TVET: Highly skilled and industry-ready | New Straits Times. (2021). Retrieved 25 June 2021, from https://www.nst.com.my/education/2020/03/573724/tvet-highly-skilled-and-industry-ready

Malaysia Digital Economy Blueprint. (2021). Retrieved 25 June 2021, from https://www.epu.gov.my/sites/default/files/2021-02/malaysia-digital-economy-blueprint.pdf